|

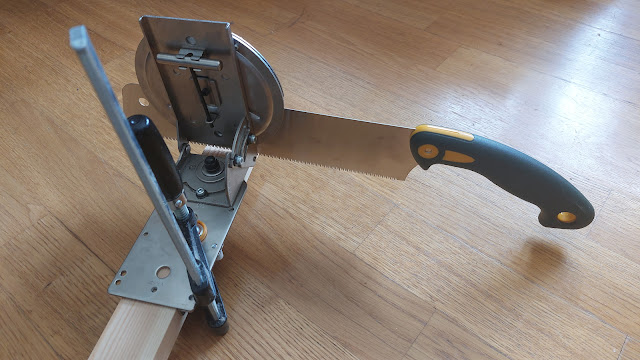

| Piece clamped into position, the saw in place. |

Decades ago, as a naive young man, I bought the cheapest possible plastic mitre box and assumed I could easily create wooden frames for paintings. Didn't happen.

Decades passed.

Now, Facebook ads, of all things, pushed this device that might be the ultimate compact hand-sawing assist. It's not one of those space-eating mitre saw contraptions, here the saw blade passes through between aligned metal plates. It's fairly small and should also help in longer parallel cuts.

Apart from that the guide does any angle, compound angles, it's quite easy to apply and the cut is precise and even.

|

| The dual adjustment for vertical angle. |

Adjusting the device is a little trickier. Although it's heavy and sturdy, there's no immediate "lock" for accurate 90 degree position. Sure, there are markers but these are far from the kind of definition you'd find in a vernier caliper, for example. For the vertical alignment, two adjustments are needed.

Just eyeballing the markers isn't enough to ensure proper angle. Either you use the scribe-dummy plane-cut method as described in the manual, or you calibrate the angle against a smooth surface with a really good try square.

The device is somewhat lacking in surfaces for doing such a calibration. The vertical is easy to set, as there's a lot of surface to put a try square against. The sticker is somewhat in the way, and this is a good reason to remove it.

|

| Calibrating the guide vertically. Here still trying to avoid the sticker. |

The horizontal is harder to set, as there's even less surface to work with. But it's possible to lower the guide portion below the table surface level, and "pull" the backside of the guide against a corner of a piece that's known to be 90-degree accurate. (Easier said than found...)

All in all, I believe the guide is meant to support the scribing method described in the manual. So, everything needs to be checked before committing to a cut. The process can be either meditative and interesting, or just frustrating.

|

| Calibrating horizontally against a corner. |

Two additional items were included in the set, intended to help identify the correct angle. One is an angle protractor. It is a minimalist item, but testing it against a try square it does produce accurate angles.

The second item is a "dummy plane", a .6 millimeter thick bladeless plane for verifying the marked line and adjusting the guide into place.

The whole circular guide element can be moved vertically, by releasing the knob. This is more essential for the angled cuts, but even with a straight cut it can be useful to drop the guide against the piece as the sawing proceeds.

|

| Some of the extras. The 90-degree guide is attached. |

There are also a couple of attachments, a removable handle and two guides. One guide helps with parallel sawing, the other is for cuts. With long parallel cuts, it's expected the saw guide moves with the saw as the cut advances.

I'm not super confident about the guides, as their placement appears slightly less than absolute. I'd also recommend using two clamps rather than one, when attaching to a piece.

A variant of a kataba-type saw (backless, thick, general purpose) is included with the set, and as is with these Japanese saws, it operates by pulling rather than pushing. With the way the guide works, a backless saw is a necessity.

The grip is removable and can be attached upside down too.

|

| Another angle, showing the adjustment key at its home. |

A sore point here are repeats, which the device cannot really solve on its own. You'd need a fairly extensive jig/guide to be able to do both adjustable and repeated parallel cuts.

There are nice details, the T-shaped allen/hex type adjusting key has a home inside the guide, and it's best kept there when not needed.

Like I said the ground plane of the guide is sturdy, in addition it is easy to attach to tables and other pieces using clamps, especially after removing the handle (not pictured) out of the way. The plane also has enough holes to attach it semi-permanently to a jig.

|

| Result. |

A good try square is needed to test if the result is properly 90 degrees.

I won't pass a full verdict now, as the pieces I've worked with are not that precise to begin with. But it does seem some attention is needed to get best results. I could find some lopsidedness in one corner, but for most practical purposes, the wood end is as good as perpendicular.

All in all, I'm more positive about this device as I gain practice. For anyone who has access to electric saw, it might seem slow, but it's better and faster for the job than anything I've had before.

I likely wouldn't recommend this guide on very thick pieces, and some reviews seem to suggest as much. It's logical, the more the saw comes out from the guide, the more potential there is for drifting.

For my purposes a guide with a rigid 90 degree angle might have been more useful... and I did actually get another, simpler guide. It's early days, but both seem to have pros and cons. More about that in another post.